Established in 1994, we deliver tailored solutions to small businesses and large industrial companies.

Contacts

Arrange an appointment with us directly or at your location...

Established in 1994, we deliver tailored solutions to small businesses and large industrial companies.

Arrange an appointment with us directly or at your location...

rolls production and service, on-site service, lubrication systems, pulping technology, winding shafts and manipulation, showering systems, edge trimming devices, nozzles, rotary joint spares and many more ...

Poor lubrication is a major cause of bearing failure (over 36%). SKF provides high-quality, tested lubricants tailored to your needs, backed by expertise for optimal solutions. Strict quality control ensures consistent global performance. We offer expert support for lubricant selection.

Ensure optimal machine operation with SKF manual lubrication tools. Designed for "right" lubrication – correct lubricant, quantity, timing, and location – they prevent errors and offer a comprehensive product range for all steps.

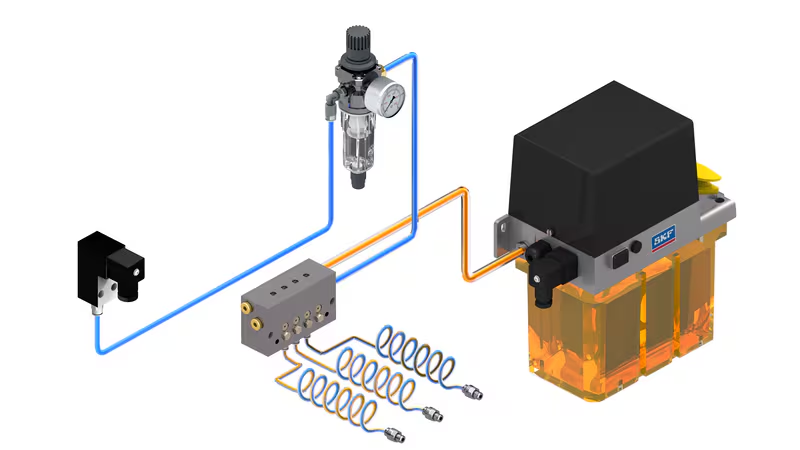

Automatic lubricators provide precise lubrication to individual points, especially hard-to-reach ones. They boost safety, maintenance efficiency, and machine reliability. A wide range of options is available.

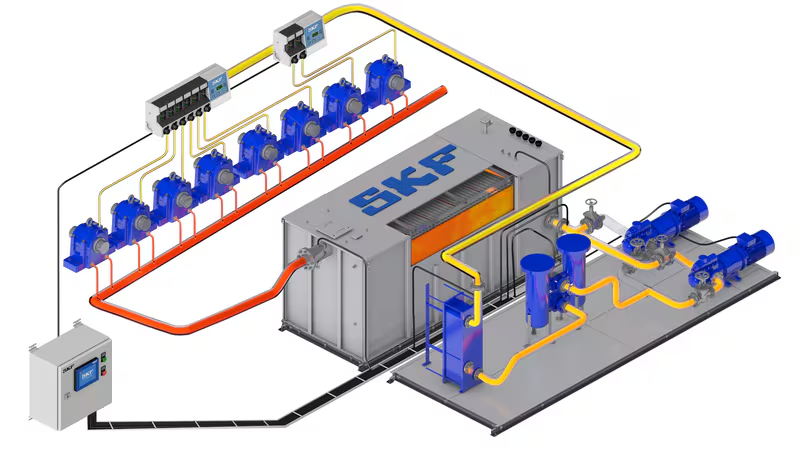

Automatic lubrication ensures accurate, timely lubricant delivery, increasing machine availability and reducing manual dependence. It minimizes wear, extends lifespan, lowers costs, reduces shutdowns, improves safety, and is environmentally beneficial for various industries.

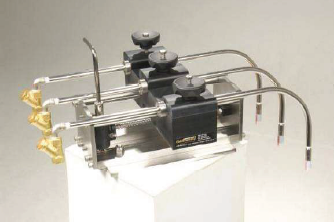

SKF offers a wide array of lubrication system components for precise lubricant delivery, optimizing machine life, safety, and cost efficiency by minimizing friction and wear. Key parts of the system are: Supply units, Lubrication pumps and pump units, Lubricant metering devices, Monitoring devices, Control units and software and accessories.

SKF RecondOil Box: Use the same oil repeatedly and get it cleaner than ever. Improve machine performance and make oil a sustainable asset, not a waste. Go circular with your oil.

We deliver tailored hydraulic power units, combining reliable standardized parts with bespoke individual components, all mounted on a sturdy tank or frame. Our Special Hydraulic Power Units are a testament to quality, crafted to precisely match the unique needs of each customer, frequently accommodating specialized applications and unusual dimensional demands with state of art engineering.

top quality inner wear parts (e.g. carbon seals, carbon guides, springs, nipples etc.) for almost all widely used rotary steam joint heads from Kadant Johnson, Voith, Valmet and others.

roll visual inspection, wall thickness measurement, coating thickness measurement, grinding, balancing, non-destructive testing, re-coating, journal replacement, bearing and other accessories reconditioning or replacement

same as standard reconditioning + bottom and journal replacement, journal repair and machining, sealing exchange, sealing surface machining, inner parts repair or replacement, manhole cover and sealing replacement, shell spot damage repair, pressure vesel test incl. certificate

suction roll inspection including comprehensive inspection report, dynamic balancing, cleaning, roll shell and cover grinding, cover regrooving, sealing strips and air tubes relacement, pilot bearing and bearings replacement, journal replacement, internal shell surface reconditioning, new shell manufacture from high quality Duplex stainless steel, optionaly with polyurethane cover incl. drilling patttern and grooving. Upgrade with smart technology for bearings and sealing strips condition monitoring

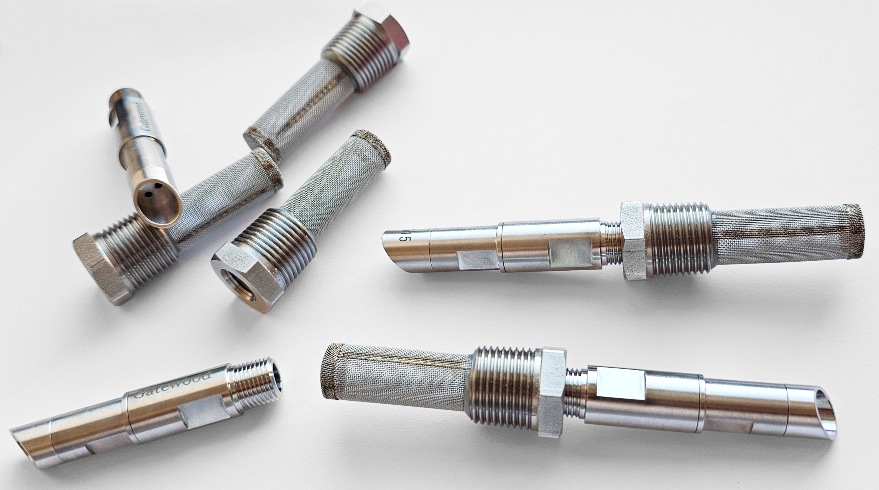

large variety of nozzle types and sizes for customers various applications. Flat jet nozzles, needle jet nozzles, mono nozzles made of stainless steel also with ceramic insert for long lasting beam quality

we are pleased to offer high quality trim nozzles and accessories from Gatewood. Trim nozzle is a long-lasting, precision, high pressure nozzle with an extremely hard ceramic tip. This tough, high quality nozzle was specially designed by Gatewood at the request of several large paper mills in need of a nozzle to withstand high pressure while maintaining the highest quality stream over long periods of time. Trimm nozzles are available in single stream, double stream and double parallel stream. Nozzles can be equiped with drip shielding and filter screen

whether you are winding or unwinding web-like materials. You can choose solutions for single or multiple reels, and for use with sensitive cores, from the diversity of this product group. We satisfy the most demanding loading requirements and allow optimum web speeds. The use of lightweight construction reduces the weight of the equipment and enables ergonomic handling, while standardization guarantees an excellent price/performance ratio.

our products can handle any reel, whether pneumatic, mechanical or combined pneumatic/mechanical. Our sophisticated engineering ensures first-class functionality. In addition, the compatibility with a wide range of different machine types and automated production processes makes the machines extremely versatile.

winding cores made of different materials and with different diameters call for a wide range of options. Ease of use, trouble-free operation and low maintenance are combined in our adapters. With low cost and reduced setup and downtime, you can accelerate and simplify your production and processing operations, reducing operating costs.

our handling systems offer significant benefits in terms of both mobility and efficiency. We ensure optimised processes in line with your individual requirements. Efficiency is increased by focusing on operational safety and ergonomics. With a convincing combination of technology and quality, our handling systems are highly versatile and easy to operate.

from vacrolls to dryers and clupaks. Cast iron or state of the art steel cylinders, welded or screwed, manufactured with excellent release and long life coatings. Accessories such as bearings, housings, turbulence bars, steam and condensate equipment available on request.

dryer cylinders for clupak units. Hard coatings for long durability with excelent anti-corrosion properties and heat transfer. Hard smooth mirror - finished surface.

grooved and drilled cylinders for use in the individual felt dryer section of high speed paper machines. We offer new Vac rolls and also on-site modification of present dryer cylinders by driling and instalation of separator chamber.

wet-end trimming machine from the world´s leading wet-end trim nozzle manufacturer Gatewood. Easy to install, unique and precise adjustments to the width of the paper, quick nozzle exchange during production.